Our Work

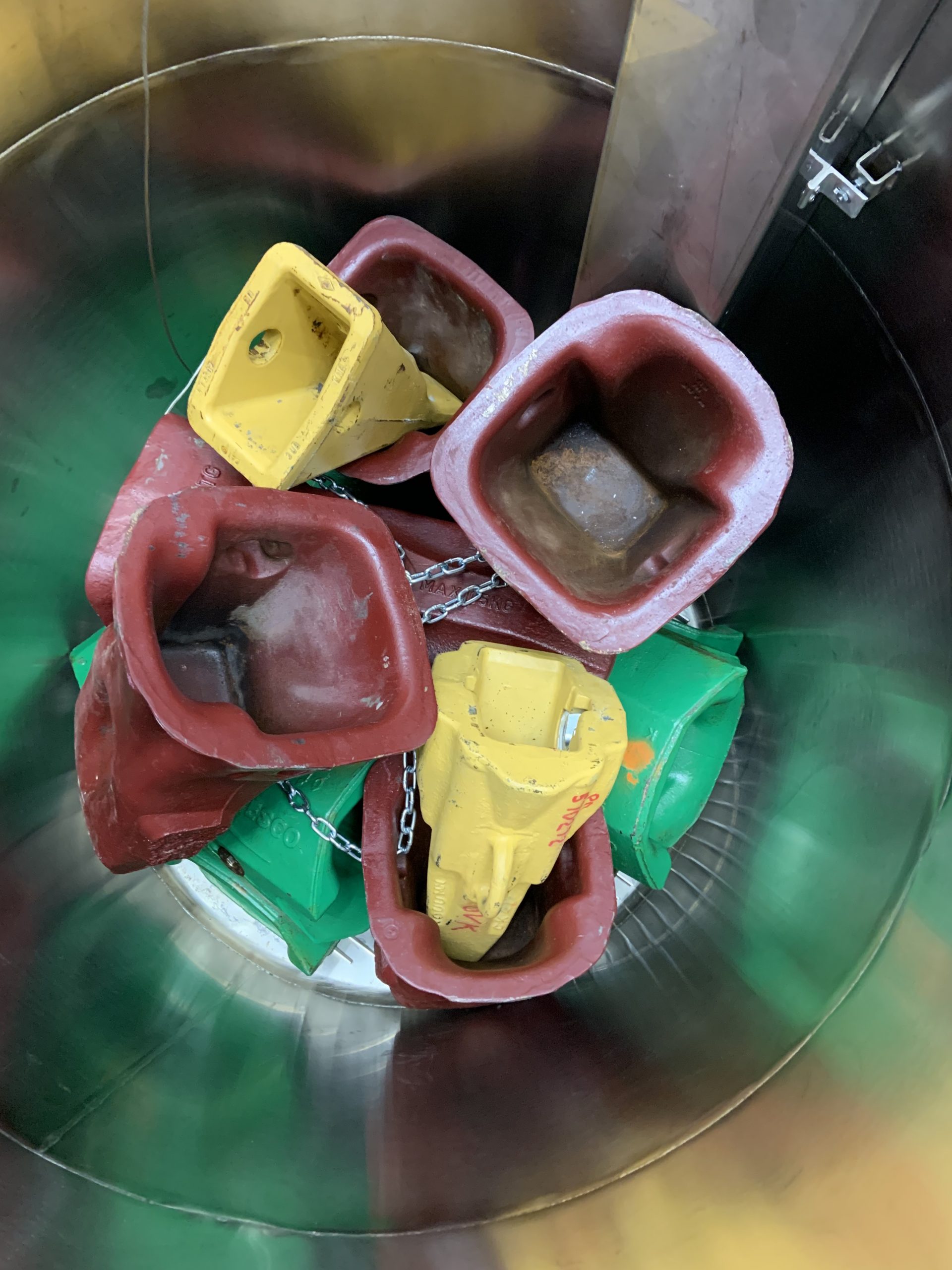

Deep Cryogenic Treatment – Bucket Teeth

A large mining corporation is striving to substantially reduce the cost of delivered ground engagement equipment by making their bucket teeth last longer through the use of Deep Cryogenic Treatment (DCT). In partnership with our technology partner, Deep Cryogenics International, Induspec created a DCT recipe for these various teeth which ranged in weight from 60 lb to over 250 lb each, manufactured by quality manufacturers such as CAT, MTG, ESCO and others.

Induspec performed a deep cryogenic treatment with multiple tempering heat treatment sequences on the 2,600 lb of bucket teeth over a period of nearly four days. These bucket teeth had been heat treated by the manufacturers to optimize wear resistance and toughness, however due to the fact that only heat treatment and not deep cryogenic treatment, was applied a further improvement in wear resistance could be gained through DCT. Typically the use of DCT on ground engagement tools will yield an extension in useful life of between 20% and 40% .

Induspec is working with our mining customer to quantify the observed benefit of the DCT. The comparison is being evaluated, not in a laboratory setting, but by actually comparing the DCT treated teeth with identical, but untreated teeth in service. Based on the result of these trials, Induspec will work with the customer to develop a financial model which quantifies the savings to be realized overall. When it comes to wear, savings are typically not only realized by having to purchase fewer wear parts, but also in the reduced maintenance labour and the increase operating time of the equipment.

- Date June 22, 2021

- Tags Deep Cryogenic Treatment