Our Work

Roll Press Rehabilitation

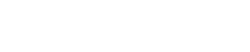

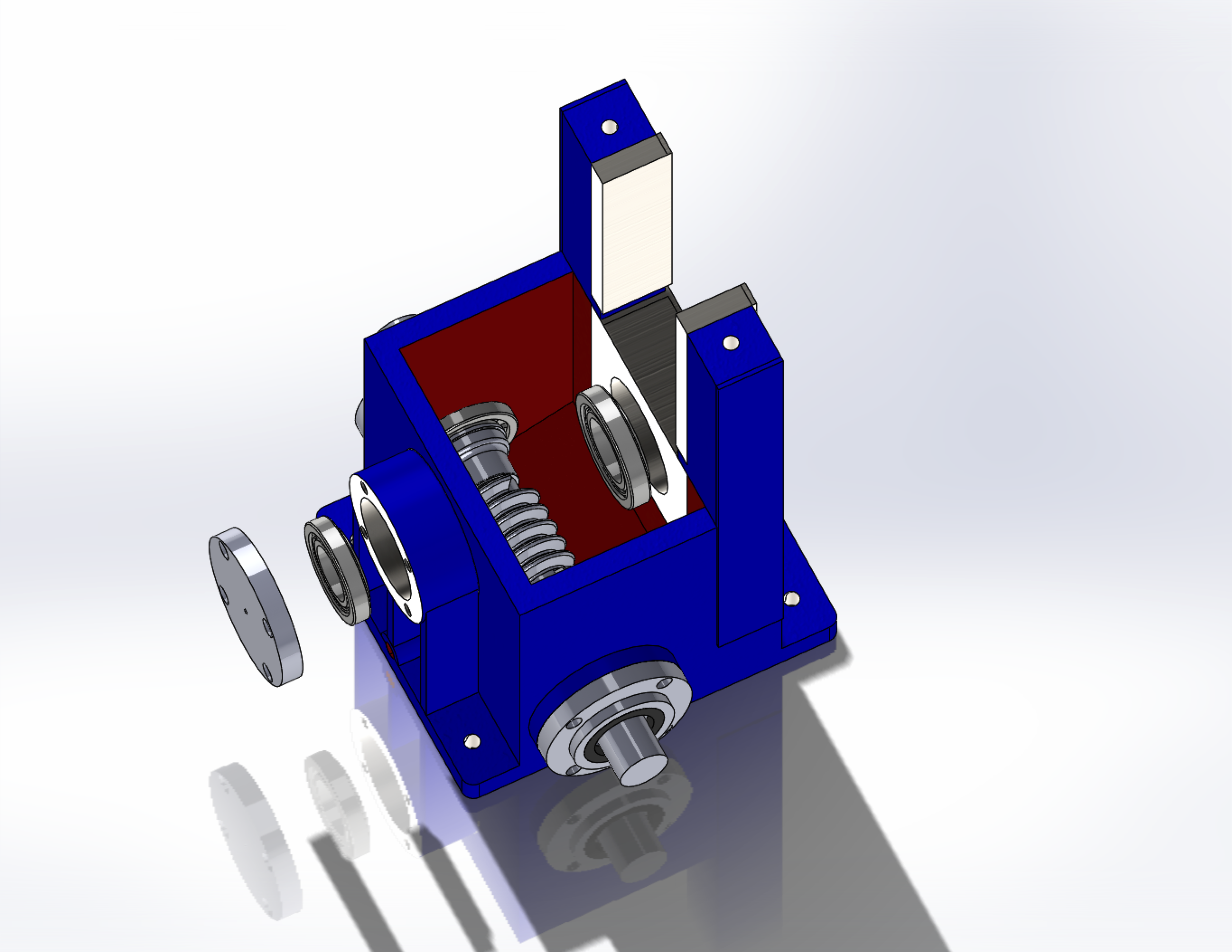

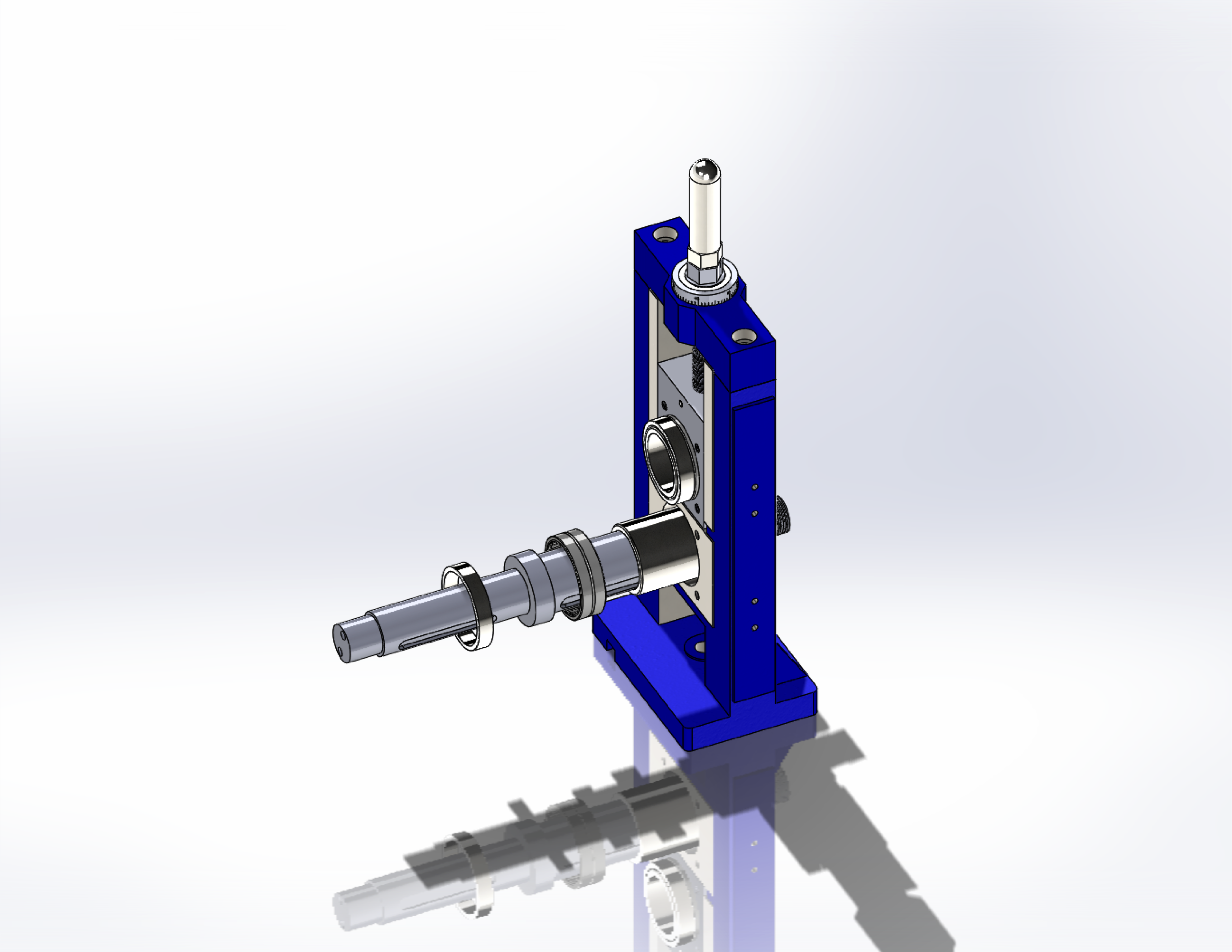

An industrial manufacturing client recently purchased a used roll press to manufacture a mining related final product. The roll press consists of seven identical press stands and the line has to reliably produce over 1000 pieces per day to meet order requirements. The line is not operating reliably and meeting production targets is a significant challenge. Induspec was retained to provide assistance with how to improve the reliability of the system. The press roll was estimated to be 50+ years old , had no spare parts, drawings, or specifications. Induspec reviewed the system and communicated an approach of reverse engineering the system. Once the reverse engineering was complete, a new press stand would be built and replace one of the existing stands. The existing stand could then be refurbished and the process repeated until all seven stands had been rebuilt. Induspec used sophisticated 3D laser scanning techniques to obtain existing shapes of gears, gearboxes, shafts, etc. The laser scans were converted to 3D models which were imported into SolidWorks, the 3D design solution which Induspec utilizes exclusively. The project is currently completing the design please with Induspec obtaining manufacturing estimates for the next step towards implementation.

- Date June 5, 2019

- Tags Industrial